SIG SAUER surprised the firearms community in 2010 with the introduction of the SIG516, it’s first offering in the AR-15 marketplace. While SIG had produced long guns over the years, the company was primarily thought of as a maker of high-quality handguns used by the police and military. What was particularly interesting about the then new SIG516 is that it was a piston-driven AR, not the traditional direct gas impingement (DGI) design. And at that time, only a few manufacturers were making piston ARs.

The original SIG516 was a tough gun, and to prove it, during a demonstration at the SIG SAUER headquarters in New Hampshire, the gun was subjected to a torture test before witnesses from the gun press. The loaded gun was buried in sand, removed and after a quick check for barrel obstructions, fired without a malfunction. Almost immediately, it was buried in thick, sticky mud, pulled out and fired, again with no malfunctions.

Then it was held under water until all voids were filled, pulled out and fired. Water does not compress and doing this with many guns would damage them, but it didn’t hurt the SIG516. During the test, the gun was also fired until the barrel was smoking then dunked in a bucket of water, immediately sending steam into the frigid air, but the bath had no ill effects.

The SIG516 was and is built for hard use and is marketed not only in the commercial market as a semi-automatic AR-15, but also in a select fire version to the police and military. It’s not meant as a hobby gun and at its introduction had an MSRP reflecting that. But as tough and well thought out that the gun was, improvements could be made.

The SIG516 was and is built for hard use and is marketed not only in the commercial market as a semi-automatic AR-15, but also in a select fire version to the police and military. It’s not meant as a hobby gun and at its introduction had an MSRP reflecting that. But as tough and well thought out that the gun was, improvements could be made.

Within a few years, SIG began introducing periodic changes making a very rugged gun easier to operate, so owners of the originals may want to consider upgrading to the newer version. Since guns generally have a good resale value, trading in the older SIG516 can offset the customer’s cost and, after resale of the trade-in, add to a retailer’s bottom line. But there must be a benefit for the shooter to upgrade, and explaining how the gun has been improved during the last several years can help make that sale.

An original SIG516 produced in 2010 was compared with the latest SIG516 Patrol. Probably the most notable improvement over the original is in the gas piston system. Where the original piston system presented some challenges in disassembly, the later version is far easier to take apart.

The original piston system worked well, but disassembly required that a spring-loaded plunger be pushed in with the help of a bullet tip or other tool while the gas valve was unscrewed from the gas block. It took quite a few turns to remove. The revised system though requires no tools and can be disassembled by pushing a plunger with finger pressure while rotating the gas valve 180 degrees.

Where the original had a chrome-lined barrel finished with a frosty nitride on the outside, the current semi-auto barrel is finished inside and out with a salt bath nitride treatment. The nitride finish makes the surface extremely hard and corrosion resistant, but is not like chrome plating that is sometimes unevenly applied. The nitride finish usually encourages more accuracy than can be expected from chrome lined barrels, and the newer test gun delivered.

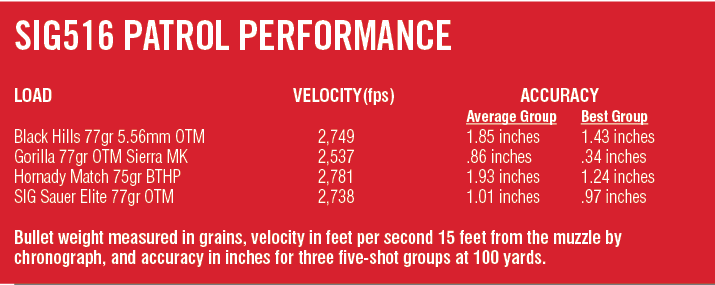

When new, the older SIG516 printed three-shot groups at 100 yards averaging from just over 1 inch to almost 3 inches, depending on the ammunition used. However, the refined model delivered five-shot groups averaging less than 1 inch to just under 2 inches with a best group of .34 inch. That is especially surprising considering the SIG516 is a piston gun, which is generally considered to be less accurate than a DGI gun.

The revised SIG516 has an ambidextrous safety, where some of the early originals did not. But perhaps more important is a redesign of the bolt catch. The original had a standard AR-15 bolt catch with a narrow knob at the bottom. That caused some difficulty when engaging the catch by hand because the gun has an ambidextrous magazine release with a button on both sides of the receiver. The distance between the button on the left side below the bolt catch and the bosses where the bolt catch is attached is small, requiring careful use of just the tip of a finger instead of the finger pad to engage it.

Modifications from the old SIG516 (below) are noticeable. The newer version (above) comes with iron sights, a different buttstock and other modifications, but most notable and practical is the piston system method of disassembly, which is much easier than the original.

But the later version uses a bolt catch with a paddle that extends towards the muzzle making it easy to engage.

There’s more. Where the old gun was supplied with a standard GI-style charging handle, the current model comes with a wider ambidextrous charging handle that is easier to operate. And it also comes with a set of flip up iron sights which were lacking on the older version.

Other changes are less obvious and may or may not be of importance to the buyer. The older gun has white markings, while the markings on the newer one are just pressed into the metal. The pistol grips, while similar, are a bit different with the later version having a curved backstrap instead of a straight one. And Magpul supplied the old gun’s buttstock, while the current one is by Ark Defense and has a broader comb for a more comfortable cheek weld. Further, the old gun has a bayonet lug, which is not present on the current gun. Although any magazine built to standard AR-15 dimensions will work with either gun, the latest one is supplied with a polymer from Magpul where the old one came with a standard aluminum magazine.

The hammer on the newer gun, while similar to the standard GI hammer used on the old model, has lightening cuts to reduce weight which, according to SIG, improves performance. Likewise, the bolt carrier on the gun is now lighter weight, which again is a performance enhancer according to SIG.

The finish on both bolt carrier groups is DLC (Diamond Like Carbon) and provides more lubricity than does a salt bath nitride finish. Additionally, the bolt-on gas key common to DGI ARs has been replaced with an integral boss that cannot come loose. According to SIG, the gun will run with or without bolt gas rings, and the older model was supplied without them while the newer gun has them installed.

The receiver extension on both guns is the same Mil-Spec diameter, but the older gun sports four drain holes in the bottom while the current version has only the common small drain hole in the rear of the tube. SIG gives no particular reason for the change, but it is presumably to reduce manufacturing cost. When asked if the gun would still function when submerged in water, removed and fired, the response was yes. It appears then that the extra holes were not essential for drainage.

The receiver extension on both guns is the same Mil-Spec diameter, but the older gun sports four drain holes in the bottom while the current version has only the common small drain hole in the rear of the tube. SIG gives no particular reason for the change, but it is presumably to reduce manufacturing cost. When asked if the gun would still function when submerged in water, removed and fired, the response was yes. It appears then that the extra holes were not essential for drainage.

The older and newer versions of the gun share the same rugged characteristics, including a spring-loaded plunger in the lower that applies pressure on the upper to keep it from wobbling and, at least theoretically, improve accuracy. The receiver extension is properly staked and the extractor utilizes the correct black insert, while only the extractor on the newer gun is equipped with an O-ring.

An unusual improvement of both SIG516s, is the metal stud found inside the barrel extension that lines up with the extractor when in battery. SIG says this stud supports the extractor in case of an overpressure caused by a barrel obstruction or defective round.

There is much more to the SIG516 though than is obvious from a visual examination. To make such a serious gun, certain quality-control tests and materials are required to assure reliability under very adverse conditions. The barrel is cold hammer forged using chrome-moly-vanadium steel, is air gauged, checked for headspace, tested with high pressure proof loads twice, then re-checked for headspace. And because of some reported failures of the barrel nut on other brands of AR-15s, SIG uses a heavier nut. The bolt is made to Military Specifications from Carpenter 158 steel, is tempered, frozen and then tempered again. The upper and lower receivers are made of 7075-T6 aluminum forgings.

All this goes into making a very tough and accurate AR, that although made for serious work, can also be enjoyed by the owner who just wants to have a high quality and unique AR-15. By educating customers about the features and benefits of the SIG516 and the improvements made since its introduction, retailers can increase sales.

For more information, contact SIG SAUER, Inc., Dealers & Commercial Sales, at (866) 345-6744 or visit www.sigsauer.com.